Introduction: Understanding Bearing Buddy Hub Kit

A bearing buddy hub kit is essential for maintaining wheel and axle performance. It protects bearings from dirt, water, and contaminants while reducing friction. Proper understanding of its components, installation, and maintenance ensures smooth operation and longevity. This guide provides a complete overview for DIY enthusiasts and professionals to use the kit effectively.

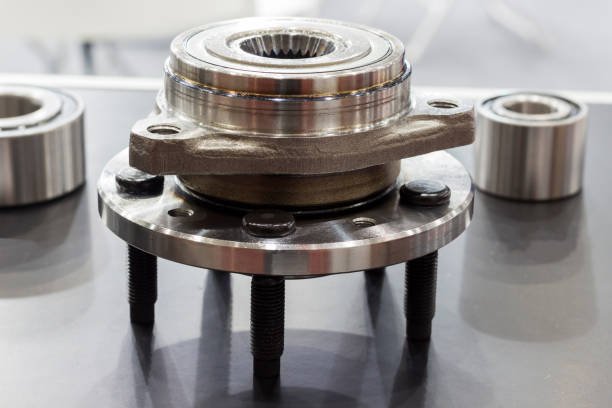

Key Components That Make Hub Kits Essential

The bearing buddy hub kit contains multiple components designed to work together for optimal performance. Knowing these parts helps with proper installation and maintenance. Each component contributes to smooth rotation, reduced wear, and extended life. Understanding them is essential for reliable operation.

Hub Body and Bearing Housing

The hub body and bearing housing form the core of the assembly. They support the wheel and house the bearings, ensuring smooth rotation under load. A sturdy hub body minimizes vibration and wear. Proper alignment during installation is critical for long-term performance.

Seals and O-Rings

Seals and O-rings prevent dirt, water, and other contaminants from entering the hub assembly. They maintain lubrication inside while keeping contaminants out. Proper inspection and replacement of worn seals are crucial. High-quality seals enhance durability and reliability of the kit.

Grease Fittings

Grease fittings allow easy lubrication of the bearings without disassembly. They ensure consistent lubrication, reducing friction and preventing overheating. Regular greasing through fittings extends bearing life significantly. Correct grease type and amount are essential for optimal performance.

Locking Nuts and Bolts

Locking nuts and bolts secure the hub assembly in place. Proper torque ensures that the hub does not loosen during operation. Over-tightening or under-tightening can cause premature wear. Using the correct hardware improves safety and reliability of the kit.

Protective Caps

Protective caps cover the hub assembly and grease fittings. They shield components from dirt, moisture, and debris. Caps help maintain proper lubrication and prevent contamination. Installing them securely enhances the longevity and effectiveness of the hub kit.

Benefits Users Gain

A properly installed bearing buddy hub kit provides multiple advantages that improve vehicle performance. It ensures smooth wheel rotation, prevents premature wear, and extends bearing life. Correct installation reduces maintenance costs and improves operational safety. Users who follow best practices enjoy enhanced reliability and efficiency.

-

Reduces friction and heat

-

Extends bearing life significantly

-

Prevents contamination from dirt and water

-

Minimizes maintenance costs

-

Ensures safer driving or towing

Step-by-Step Installation Guidance Tips

Proper installation is vital for the bearing buddy hub kit to function correctly. Following expert steps ensures smooth operation, reduces errors, and enhances durability. Understanding alignment, lubrication, and secure fastening is essential for a successful setup.

Preparing the Hub Properly

Clean and inspect the hub for wear before installation. This step prevents potential damage and ensures a smooth fit. Proper preparation also reduces long-term maintenance issues.

Lubrication Techniques for Longevity

Greasing bearings appropriately reduces friction and prevents overheating. Use high-quality grease in recommended amounts for optimal performance. Regular lubrication keeps the assembly running smoothly.

Fitting the Hub Kit

Align the kit carefully with the axle and press it in place. Correct alignment ensures smooth rotation and prevents wear. Proper positioning is key for long-term reliability.

Securing the Assembly

Tighten locking nuts and bolts according to manufacturer instructions. Install grease fittings and protective caps correctly for safety. Proper securing ensures that the hub operates without vibration or loosening.

Maintenance Strategies for Smooth Operation

Regular maintenance ensures the bearing buddy hub kit remains functional and durable. Routine inspection, cleaning, and lubrication are key practices. Monitoring the kit helps identify issues early and prevents costly repairs.

Routine Inspection Tips

Check bearings, seals, and hub components frequently. Early detection of wear prevents failures. Regular inspection also ensures optimal performance and safety.

Proper Greasing Schedule

Grease the hub at recommended intervals to maintain smooth operation. Avoid over-greasing, which can damage seals and bearings. Correct greasing enhances reliability and longevity.

Identifying Common Issues

Unusual noises, vibrations, or heat indicate potential problems. Address these promptly to avoid serious damage. Early troubleshooting prevents major breakdowns and expensive repairs.

Tools Needed For Installation And Maintenance

Having the right tools ensures accurate installation and easy maintenance. Quality tools reduce risk, improve efficiency, and make routine checks simpler. Professionals and DIY users benefit from having the correct equipment.

-

Torque wrench for precise tightening

-

Bearing pullers or press tools

-

Grease gun

-

Cleaning brushes

Comparing Hub Kits With Standard Assemblies

Bearing buddy hub kits provide distinct advantages over standard hub assemblies. They simplify maintenance, enhance performance, and extend bearing life. Understanding these differences helps users select the right hub solution.

-

Easier lubrication with grease fittings

-

Reduced contamination risk

-

Longer bearing life

-

Simplified maintenance process

Common Installation Mistakes To Avoid

Awareness of common mistakes ensures optimal performance and longevity. Errors during installation or maintenance often lead to early failures. Knowing what to avoid ensures long-term reliability and smooth operation.

-

Using incorrect grease types

-

Over-tightening or under-tightening nuts

-

Neglecting regular inspections

-

Misalignment during installation

Advanced Tips For Maximum Longevity

Following expert techniques improves performance and extends lifespan. Using high-quality components, proper lubrication, and monitoring ensures reliable operation. Heavy-duty applications benefit most from these advanced practices.

-

Use premium bearings and seals

-

Apply heat-resistant grease for high loads

-

Monitor hub temperature regularly

-

Keep spare parts for quick replacements

Future Trends in Hub Kit Technology

Hub kits continue evolving with better materials, protective designs, and lubrication systems. These improvements enhance reliability, performance, and ease of maintenance. Staying updated helps users adopt the latest innovations.

-

Self-lubricating hubs for convenience

-

Advanced seal materials for durability

-

Lightweight but strong hub designs

-

Sensor integration for real-time monitoring

-

Environmentally resistant coatings

Conclusion

A properly installed and maintained bearing buddy hub kit ensures smooth, reliable wheel and axle operation. Understanding its components, installation steps, and maintenance practices is crucial for long-term performance. Following expert tips prevents costly failures and improves safety. Regular care maximises lifespan and efficiency. Investing in a quality kit guarantees smooth operation and dependable performance.

FAQs

Q1: What is a bearing buddy hub kit?

A: It is a hub assembly kit designed to protect wheel bearings, simplify lubrication, and ensure smooth, reliable rotation.

Q2: How often should the hub kit be greased?

A: Typically, every 3,000–5,000 miles or as recommended by the manufacturer for optimal performance.

Q3: Can I install a bearing buddy hub kit myself?

A: Yes, with proper tools, instructions, and care, DIY installation is possible.

Q4: What are common problems with hub kits?

A: Noise, vibration, overheating, and premature wear due to misalignment or improper lubrication.

Q5: Why is it better than standard hub assemblies?

A: The kit simplifies maintenance, reduces contamination risk, extends bearing life, and improves overall reliability.

Leave a Reply