Introduction:

Ensuring smooth and safe towing starts with maintaining your trailer’s wheel bearings and hubs. A properly lubricated hub system reduces friction, prevents overheating, and extends the lifespan of your trailer components. Oil bath hubs are designed for heavy-duty applications, offering long-lasting lubrication and superior protection against wear, water, and debris.

This guide explores the benefits of oil bath hub systems, their operation, maintenance tips, and practical advice to ensure your trailer performs at its best under any condition.

Understanding the Role of Wheel Bearings

Wheel bearings are critical for smooth rotation and safe towing. They reduce friction between moving parts and bear the weight of the trailer.

Poorly maintained bearings can cause overheating, uneven wear, or even complete failure. Using a hub system with consistent lubrication ensures that bearings remain protected and can handle heavy loads efficiently.

Maintain Consistent Lubrication

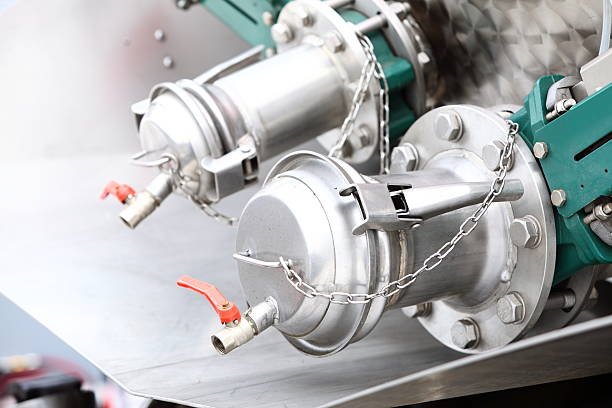

Oil bath hubs use a reservoir filled with lubricating oil to submerge a portion of the bearings. As the wheels rotate, the bearings move through the oil, ensuring constant lubrication.

Benefits include:

-

Minimizing heat buildup

-

Reducing friction for longer component life

-

Protecting against moisture and road debris

-

Maintaining smooth operation under heavy loads

This design sets oil bath hubs apart from traditional grease-packed systems, providing greater durability and reliability.

Advantages of Using Oil Bath Hubs

There are multiple reasons why heavy-duty trailers benefit from oil bath systems:

-

Extended Bearing Life: Continuous lubrication reduces wear and tear.

-

Reduced Maintenance: Less frequent servicing compared to grease hubs.

-

Enhanced Protection: Oil creates a barrier against water, dirt, and corrosion.

-

Improved Safety: Well-lubricated bearings lower the risk of overheating.

-

Optimized Towing Performance: Smooth hub rotation enhances trailer efficiency.

These advantages make oil bath hubs ideal for boat, utility, and commercial trailers.

Installation Best Practices

Proper installation is essential for reliable performance:

-

Check Compatibility: Ensure the hub fits your trailer axle and load capacity.

-

Inspect Components: Clean and inspect bearings, seals, and spindles. Replace damaged parts.

-

Fill Correctly: Use high-quality lubricating oil, ensuring bearings are partially submerged.

-

Secure Hub: Mount properly and follow recommended torque specifications.

-

Verify Operation: Rotate the hub to confirm smooth movement and oil coverage.

Correct installation prevents early wear and enhances long-term reliability.

Routine Maintenance Recommendations

Even with low-maintenance hubs, periodic checks are necessary:

-

Monitor oil levels regularly.

-

Inspect seals, bearings, and mounting hardware.

-

Replace oil based on usage or manufacturer guidelines.

-

Keep hub surfaces clean from dirt and corrosion.

Following these maintenance routines ensures optimal performance and prevents costly failures.

Applications Across Different Trailers

Oil bath hubs are versatile and widely used in:

-

Boat Trailers: Prevents damage from water exposure.

-

Utility Trailers: Supports heavy loads for work or recreational use.

-

Commercial Transport: Ideal for frequent, heavy-duty hauling.

-

Recreational Vehicles: Ensures smooth towing for campers and RVs.

Their durability and reliability make them a trusted choice across industries.

Tips for Extending Hub Life

To ensure maximum longevity:

-

Avoid exceeding trailer weight limits.

-

Clean hubs regularly to remove debris and salt.

-

Use recommended lubricating oil.

-

Schedule regular inspections.

-

Store trailers in dry conditions when not in use.

Implementing these tips keeps trailers running smoothly and safely.

Conclusion

Maintaining your trailer’s wheel bearings and hubs is essential for safe and efficient towing. Oil bath hubs provide consistent lubrication, reduced maintenance, and superior protection, making them a smart choice for heavy-duty applications.

By understanding their operation, performing proper installation, and following routine maintenance, you can maximize trailer performance, reduce the risk of failure, and ensure smooth, reliable towing for years to come.

FAQs

1. How do oil bath hubs differ from grease hubs?

Oil bath hubs provide continuous lubrication and better protection against water, debris, and corrosion compared to grease hubs.

2. How often should I check the oil?

Check oil levels before long trips and at least every few months, depending on trailer usage.

3. Can these hubs be used on all trailers?

They are compatible with most trailers, but always verify axle size and load specifications.

4. What are signs that maintenance is needed?

Unusual noises, overheating, oil leaks, rough rotation, or visible rust indicate maintenance is required.

5. How can I extend the life of my hubs?

Maintain proper oil levels, clean hubs regularly, avoid overloading, and schedule periodic inspections.

Leave a Reply